NaviTech Engineers offers comprehensive end-to-end manufacturing and engineering capabilities, tailored to meet the requirements of domestic and overseas customers across Automotive, Oil & Gas, Agricultural Equipment, Defence, Mining, Construction, and Industrial Machinery sectors.

Our operations encompass forging, casting, machining, sheet metal fabrication, and process equipment solutions — with every component precision-engineered and ready for critical applications.

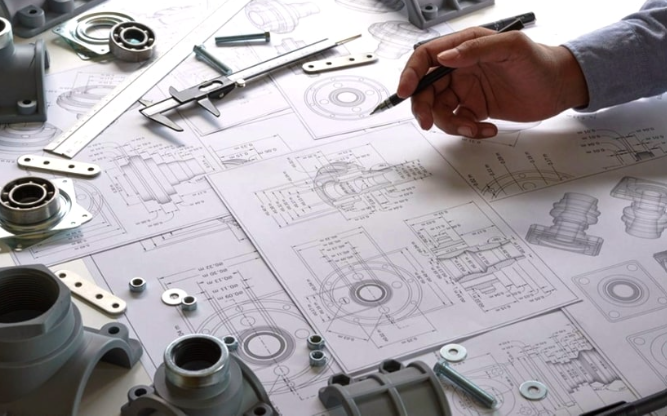

Engineering & Technical Capability

Our engineering team provides complete technical support from concept to serial production, ensuring manufacturability, cost-efficiency, and performance optimization.

Key Engineering Services

- Drawing review and feasibility analysis

- Material selection and process planning

- Tooling and die development support

- Prototype development and pilot production

- Value engineering for cost and performance optimization

Strong coordination between engineering, production, and quality ensures smooth project execution from concept to serial supply.

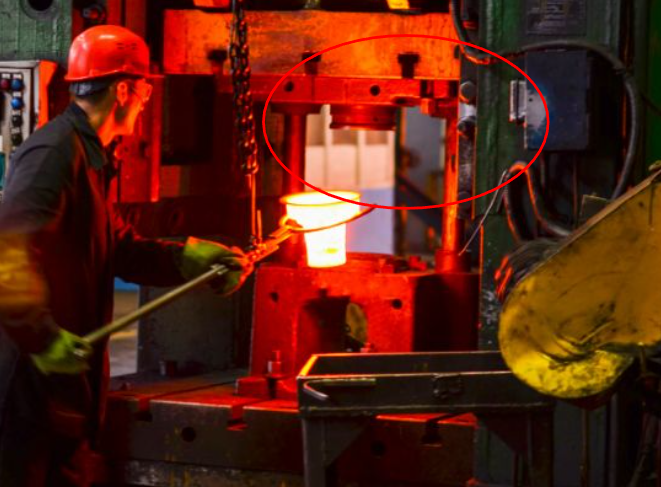

Forging Capability

Forging is one of the core competencies, enabling the manufacture of high-strength, fatigue-resistant components for critical load applications.

Forging Processes

- Open Die Forging and Closed Die Forging

- Cold Forging

Capabilities

- Controlled grain flow for strength and durability

- Precision die design and development

- Consistent dimensional repeatability

- Small to medium-size forged components

Casting Capability

Navitech supplies high-integrity cast components through approved and controlled foundry partners, ensuring metallurgical consistency and dimensional accuracy.

Casting Processes

- SG Iron (Ductile Iron)

- Grey Iron

- Aluminum Casting

- Investment Casting

- Pressure Die Casting (Al / Zn)

Key Strengths

- Sound casting with controlled metallurgy

- Machining-ready or fully machined supply

- Heat treatment and material test certification

- Suitable for structural and pressure-bearing applications

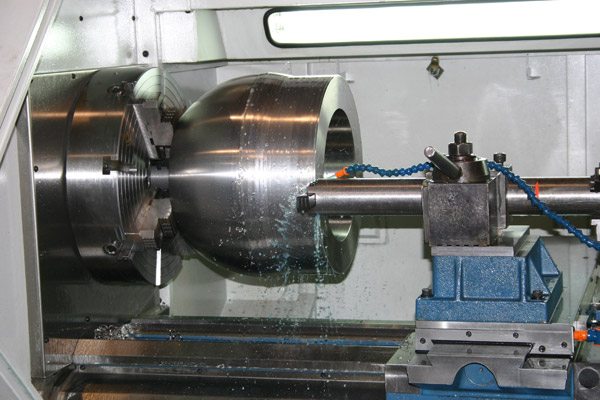

Precision Machining Capability

Precision machining operations are designed to deliver tight tolerances, repeatability, and surface finish for performance-critical parts.

Machining Facilities

- CNC Turning & Milling

- VMC & HMC Machining

- Precision Boring, Drilling, Tapping

- Grinding, Honing & Surface Finishing

- Sub-assemblies & kitted parts

Secondary Operations

- Grinding and Honing

- Surface Finishing

Machining Strengths

- Close-tolerance components

- Complex geometries

- Sub-assemblies and integrated solutions

- 100% inspection for critical dimensions

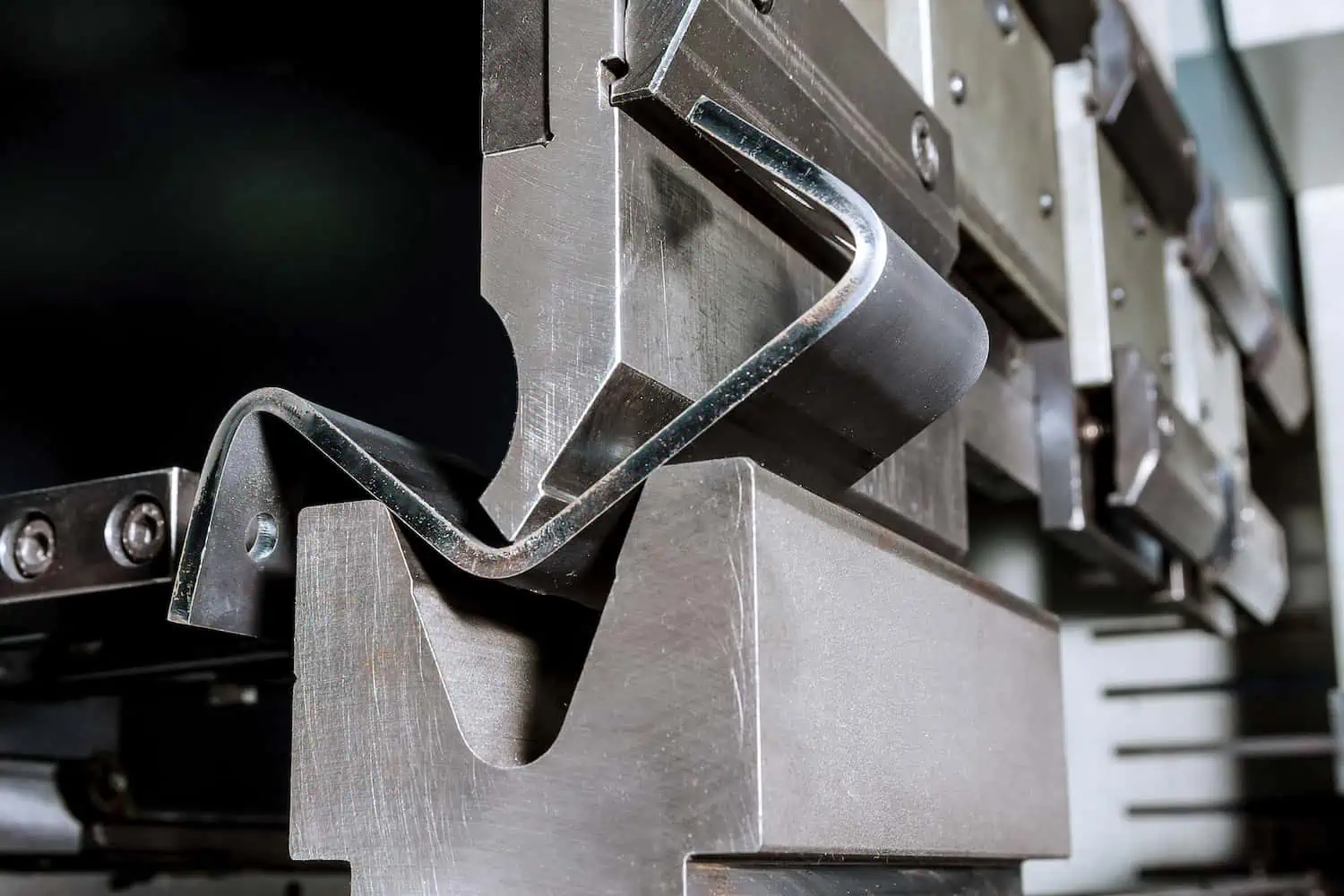

Sheet Metal & Fabrication Capability

Custom sheet metal and fabricated assemblies are supplied for industrial and export applications.

Processes

- Laser Cutting

- CNC Punching

- CNC Bending & Forming

- MIG, TIG & Spot Welding

Fabricated Products

- Equipment Frames & Skids

- Electrical & Industrial Enclosures

- Brackets, Panels & Structural Assemblies

Surface Treatment

- Powder Coating and Epoxy Painting

- Galvanizing & Corrosion Protection

Quality & Inspection Capability

Navitech maintains a robust inspection system supported by calibrated equipment and advanced methods, ensuring dimensional accuracy, material compliance, and functional reliability.

Dimensional Inspection Equipment

- Digital Vernier Calipers (0–1000 mm)

- Outside & Inside Micrometers

- Height Gauges with Granite Surface Plates

- Bore Gauges & Dial Bore Indicators

- Profile Projector (Optical Comparator)

Advanced & Critical Inspection Equipment

- Coordinate Measuring Machine (CMM)

- Surface Roughness Tester (Ra, Rz)

- Roundness & Cylindricity Measurement

- Dial Indicators & Lever Gauges

- Go / No-Go Gauges & Thread Plug / Ring Gauges

Material & Mechanical Inspection

- Hardness Testing Machine (Rockwell / Brinell)

- Coating Thickness Gauge

- Spectrometer / PMI Testing (Third-party, when required)

Quality System Support

- Calibration Traceable to NABL / ISO Standards

- SPC Monitoring for Critical Characteristics

- Inspection Records & Dimensional Reports

- PPAP, ISIR & Customer-Specific Documentation

Export & Global Supply Support

NaviTech Engineers supports export-oriented programs with a clear understanding of international customer requirements, documentation, and logistics.

Export Readiness

- Compliance with international standards (ASTM, EN, ISO, DIN, SAE)

- Material test certificates and inspection reports

- Controlled packaging for overseas shipment

- On-time delivery with logistics coordination

Experience in supporting global automotive, oil field, agricultural, defence, and mining applications enables reliable long-term partnerships with overseas customers.

Supply Chain & Delivery Management

Our supply chain and delivery system ensures consistent quality, flexibility, and on-time performance for both domestic and international programs.

Supply Chain & Delivery Features

- Approved and audited supplier base

- Capacity planning and delivery commitment

- Flexible batch sizes

- Consistent on-time performance