Navitech Engineers crafts a world-class portfolio of precision-engineered components and integrated assemblies — manufactured through advanced forging, casting, machining, and fabrication — delivering uncompromising performance to the world’s most demanding industries.

Every piece is produced to exact customer specifications, certified international standards, and rigorous quality protocols — with full traceability, material certification, and export-ready excellence.

Forged Components – For Critical Load Applications

Forging is the cornerstone of Navitech’s engineering excellence, producing ultra-high-strength, fatigue-resistant components designed for life-critical and extreme-duty environments. Powered by advanced mechanical and hydraulic presses, precision-engineered dies, and tightly controlled heat treatment cycles, we deliver flawless dimensional stability, superior grain structure, and unmatched durability.

Trusted by Automotive, Oil & Gas, Defence, Mining, and Heavy Industrial sectors worldwide, our forgings endure the harshest loads and conditions. Backed by expert craftsmanship and state-of-the-art infrastructure, Navitech supplies premium, export-grade forgings tailored precisely to your requirements.

Key Forged Parts

- Transmission & Drive Shafts

- Axle Shafts & Stub Axles

- Gear Blanks & Ring Gears

- Flanges (Oil Field & Industrial Grade)

- Connecting Rods & Yokes

- Couplings & Universal Joint Components

- Steering & Suspension Forgings

- Mining & Construction Equipment Forgings

Forging Capabilities

- Open Die & Closed Die Forging

- Precision Die Design & Development

- Controlled Grain Flow for Critical Components

Surface Finishing

- Shot Blasting

- Painting

Casting Components – Structural & Functional Parts

Navitech delivers world-class casting solutions for complex, high-precision structural and functional components. Leveraging green sand, no-bake, and investment casting technologies — supported by state-of-the-art melting furnaces and meticulous fettling — we achieve superior dimensional accuracy, exceptional surface finish, and consistent metallurgical properties.

Serving Automotive, Oil & Gas, Agriculture, and Heavy Machinery markets, our castings meet the highest global quality and performance standards. With integrated heat treatment and surface finishing, every part is supplied ready-to-install or fully machined — engineered for reliability and longevity.

Casting Processes

- SG Iron (Ductile Iron) Casting

- Grey Iron Casting

- Aluminum Casting

- Investment Casting (Precision Components)

- Pressure Die Casting (Al / Zn)

Critical Casting Parts

- Gearbox Housings

- Hydraulic Pump & Valve Bodies

- Differential & Axle Housings

- Engine Brackets & Mounts

- Oil Field Equipment Housings

- Agricultural & Tractor Cast Components

- Mining Equipment Structural Parts

Advantages

- Casting with controlled metallurgy

- Machined-ready or fully machined supply

- Heat treatment & material test certification

- Suitable for export and high-performance applications

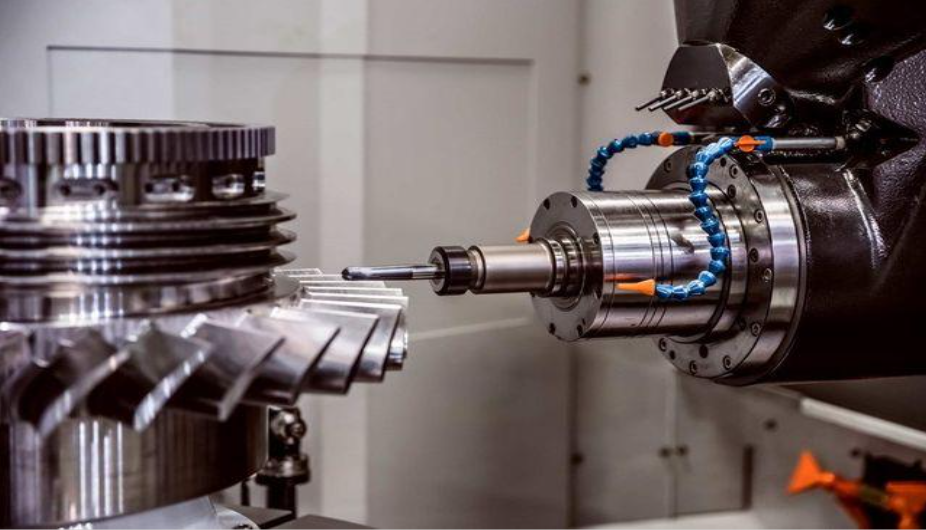

Precision Machined Components – Close Tolerance Parts

Navitech’s state-of-the-art machining division produces ultra-precise, performance-critical components with exceptional accuracy and repeatability. Equipped with advanced CNC turning centers, VMC/HMC machines, precision boring, grinding, and honing systems, we achieve mirror-like surface finishes and tightest tolerances.

Serving Automotive, Defence, Oil & Gas, and Industrial sectors, our machined parts include shafts, housings, flanges, and valve components — with full capability for sub-assemblies and kitted solutions.

Machining Capabilities

- CNC Turning & Milling

- VMC & HMC Machining

- Precision Boring, Drilling, Tapping

- Grinding, Honing & Surface Finishing

- Sub-assemblies & kitted parts

Critical Machined Parts

- Hydraulic Pump Components

- Valve Spools & Sleeves

- Precision Shafts & Pins

- Bushes, Sleeves & Spacers

- Flanges & Couplings

- Oil & Gas Machined Fittings

- Defence & Aerospace Support Components

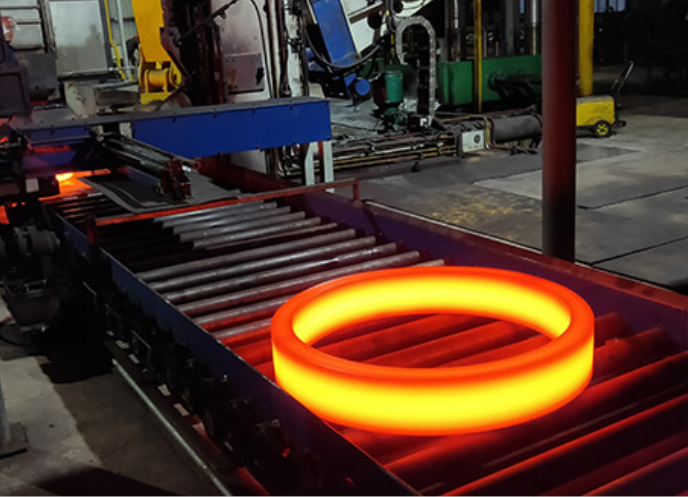

Ring Rolling – Seamless High-Integrity Rings

Ring rolling is a specialized forming capability at Navitech Engineers, enabling the manufacture of seamless rings with superior grain flow, high strength, and excellent dimensional accuracy for critical applications.

Our controlled ring rolling process, supported by precision tooling, close dimensional control, and heat treatment, ensures uniform material properties, reduced material waste, and consistent performance across demanding applications.

We supply ring-rolled components for Automotive, Oil & Gas, Defence, Mining, and Industrial sectors, where reliability under high stress and cyclic loads is essential. With strong process control and export-focused quality systems, Navitech delivers customized, high-integrity ring-rolled components meeting international standards and customer specifications.

Typical Ring-Rolled Components

- Gear Rings & Gear Blanks

- Flanges & Spacer Rings

- Slewing Rings & Support Rings

- Seal Rings & Pressure Rings

- Structural Rings for Heavy Equipment

Key Process Advantages

- Seamless construction with optimized grain flow

- High strength and fatigue resistance

- Excellent material utilization with reduced machining loss

- Uniform mechanical properties across the section

- Suitable for heat treatment and precision machining

APPLICATION SECTORS

- Automotive & Off-Highway

- Oil Field & Energy Equipment

- Defence & Strategic Applications

- Mining & Heavy Engineering

- Industrial Machinery

Sheet Metal & Fabricated Assemblies

Navitech excels in high-precision sheet metal fabrication and complex structural assemblies for demanding industrial applications. Powered by CNC laser cutting, punching, bending, and premium MIG/TIG/spot welding, we deliver parts with exceptional accuracy, strength, and finish.

We seamlessly integrate forged, cast, and machined elements into ready-to-install assemblies, enhanced by advanced surface treatments — powder coating, epoxy painting, and galvanizing — for maximum durability and corrosion resistance.

Sheet Metal Processes

- Laser Cutting

- CNC Punching

- CNC Bending & Forming

- MIG, TIG & Spot Welding

Fabricated Products

- Equipment Frames & Skids

- Electrical & Industrial Enclosures

- Brackets, Panels & Covers

- Machine Guards & Structural Assemblies

Surface Treatments

- Powder Coating & Epoxy Painting

- Galvanizing & Corrosion Protection

Process Equipment

RO Water

Navitech Engineers designs and manufactures state-of-the-art hygienic process equipment tailored for RO packaged drinking water plants and modern milk dairy operations — delivering unmatched reliability, compliance, and performance.

RO Water Process Equipment

- Raw Water Storage Tanks

- Multi-Grade Sand Filter (MGF)

- Activated Carbon Filter (ACF)

- Micron Cartridge Filters

- Reverse Osmosis (RO) System

- UV Sterilizer & Ozonation Unit

Filling & Packaging

- Bottle & Pouch Filling Machines

- Rinsing & Capping Machines

- Sealing & Shrink Wrapping Systems

- Batch Coding & Labeling Units